Содержание

The stop station allows the PLC to control and monitor the flow of pallets on the conveyor with the help of sensors and actuators that are built into the stop stations. The PLC can control and monitor the flow of pallets on the conveyor with the help of sensors and actuators that are build into the stop stations. Techopedia™ is your go-to tech source for professional IT insight and inspiration.

Innovation and Smart Manufacturing – Quality Magazine

Innovation and Smart Manufacturing.

Posted: Thu, 15 Sep 2022 04:00:00 GMT [source]

Amid the jargon, it’s easy to lose sight of the benefits that CIM delivers. Somewhere in the 1980s, the industrial automation community initiated the development of computer-integrated manufacturing systems. These were systems of systems aiming to integrate Computer Integrated Manufacturing automated workstations into fully automated factories. In fact, this community was designing and developing systems of systems before it became a popular topic in systems engineering. Unfortunately for industrial automation, the results were underwhelming.

Agile Manufacturing Strategic Options

The expertise required to develop a computer integrated manufacturing system is very versatile. However, especially important are the ones related to data collection, processing, and storage – namely IoT, big data, and cloud. These technologies are integral to more complex ones, such as robotics, computer vision, and others.

CIM must be thought of as a strategic policy within a company. It can be costly, and can require changes in policies that may be difficult for those accustomed to the old methods to accept. Operational efficiency focuses on the improvement in internal customer performance and is measured in terms of flexibility, consistency, productivity, and cycle time.

Software Architectures And Tools For Computer Aided Process Engineering

However, regardless of naming and modeling, manufacturers fundamental needs have not changed significantly. What has changed is the availability of commercial software, experience in applying software applications to manufacturing, and the emergence of standards for applying software and computer technology to manufacturing. This client had computer vision algorithms created by another provider. So, we found a top-notch CV specialist to run the computer vision workstream. After our experts carefully examined the existing algorithms, they decided to redevelop them entirely.

- Lack of understanding the technology and suitable infrastructures, contributes to managers failure to appreciate CIM.

- Based on calculations for different scenarios, you can understand the advantages of implementing computer integrated manufacturing.

- This may seem complicated, but it streamlines the whole manufacturing process.

- Also, big data and AI can help you with predictive maintenance.

- The Computer Integrated Manufacturing Open System Architecture was proposed in 1990 by the AMCIE consortium to provide an open systems architecture that specifies both enterprise modeling and enterprise integration required by CIM environments.

- Maintenance tasks may also be introduced to compensate the use of facilities with low reliability indexes.

It identifies affected assets and provides the user with various information needed for reactive maintenance scenarios as well as equipment control functions from mobile. In this case, CV can analyze new images and compare them to an already existing dataset to find anomalies and prevent potentially dangerous situations on production lines and manufacturing sites. CV systems are widely used for tool and detail positioning on the production lines. The system identifies the location of an object and sends these coordinates to the robot. Our people Achieving your goals is much easier with a strong team by your side. It is made up of savvy entrepreneurs, industry experts, and technology enthusiasts who work together towards a common vision.

The increase in scalability is one of the important benefits of the technical advances in information technologies because nonscalable processes require huge capital expenditure for production system capacity changes. The automotive, aviation, space, and shipbuilding industries use computer-integrated manufacturing. The term “computer-integrated manufacturing” refers to both a manufacturing method and the name of a computer-automated system that organizes a manufacturing enterprise’s engineering, production, marketing, and support functions. Computer-integrated manufacturing is the manufacturing approach of using computers to control entire production process.

Success Measures Of Information Systems

With the emergence of Java and Web technologies, web-based production systems have been designed to share information over Internet. In this era of e-manufacturing, it is possible to perform designing, fabrication, and delivery of a component at different places across the globe. Moreover, global logistics has imparted more flexibility to production systems by providing easier transportation of raw materials and finished goods and other services like networking, packaging, warehousing, optimal routing, etc.

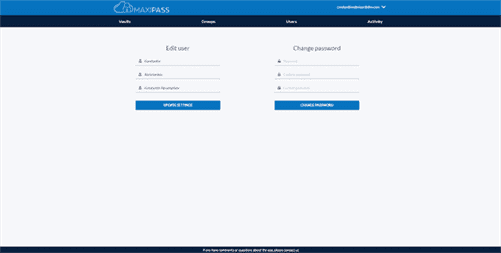

ERPAG is an enterprise resource planning solution that runs cloud-based. It is suitable for small and medium-sized businesses in a variety of industries. Such as automotive, retail, education, information technology, and others. The primary features are sales management, purchasing, manufacturing management, accounting and finance, inventory management, reporting, and analytics. With CIMOSA also the concept of an “Open System Architecture” for CIM was introduced, which was designed to be vendor-independent, and constructed with standardised CIM modules.

The full form of these technologies is computer-aided design and computer-aided manufacturing. Other than CAD and CAM, CIM involves many more technologies, such as robotics, computer-aided engineering, EMS , and more. HashMicro, a major developer of computer-integrated manufacturing software, helps many large and small businesses with their day-to-day operations. In general, Computer-Integrated Manufacturing is a concept/philosophy for integrating multiple business operations with automated functions in a production system.

Cimosa

The CIM approach has found a wide range of applications in industrial and production engineering, mechanical engineering and electronic design automation. CIM increases the manufacturing productivity and lowers the total cost of manufacturing. It also offers great flexibility, quality and responsiveness. Companies nowadays depend heavily on computer-integrated manufacturing.

It also automates the ordering of raw materials to ensure that the manufacturing process doesn’t stop. Some of its features include order fulfillment, manufacturing management, billing, and reporting. Company’s efficiency increases through work simplification and automation, better production schedules planning and better balancing of production workload to production capacity. Presents enabling philosophies, tools, or technologies of agile manufacturing, along with their functions or objectives and the means of achieving them.

Multiplatform Computer Vision Mobile Application

Our team also designed the architecture of the multiplatform computer vision mobile application and is responsible for its development (end-to-end). The application covers object detection, package damage detection, OCR, and NLP for document processing. Also, we contributed to the development of the Fluke data platform — an IoT software platform supporting a suite of apps. In case of an issue, the indicator appears on the screen in real-time that allows taking appropriate actions immediately. Our client is the global leader in the manufacture, distribution, and service of electronic test tools and software. The client requested the development of multiple solutions in the field of enterprise asset maintenance.

Computer Integrated Manufacturing curriculum introduces students to automation and industrial applications of Computer Integrated manufacturing applications. The curriculum addresses the systems approach to manufacturing and how to manage, maintain and optimize a production process. Ultimately, the goal is to achieve maximum efficiency, closing those gaps that obstruct productivity and result in the bottom-line taking a hit. Additionally, CIM plays a key role in gathering relevant, real-time data from the production floor. For instance, to optimize efficiency, CIM can monitor the operational performance of vital equipment.

Objectives Of Computer Integrated Manufacturing

With the help of industrial IoT, 3D printing, and robotics itself, you can boost the quality and consistency of the production process, as well as the final product. Also, IoT enables real-life condition monitoring of your machines and their predictive maintenance. In the competitive business arena companies must continually strive to create new and better products faster, more efficiently, and more cost effectively than their competitors to gain and keep the competitive advantage.

Data Analytics

A gravity-operated feeder for delivering parts to a robotic materials handling or machine tending operation. A microswitch sensor detects the presence or absence of parts and communicates with the robot controller by means of I/O connections. Arguably the biggest benefit of https://globalcloudteam.com/ CIM is the increase in output capacity it brings. Manufacturing enterprises can go from concept to completion in rapid time, meaning they can produce more in shorter timeframes, which has a positive impact on profitability, customer retention and attracting new customers.

Researchers and practicing engineers will also find this book quite useful. We have tried to make the book as student-friendly as possible. The book can be used in industries, technical training institutes. If it is applied correctly, it will enhance the productivity of the whole factory. It usually is installed through a LAN, or local area network, connection. OpenCIM is a complete software package for the operation, control and simulation of CIM systems.

Students learn to overcome common welding problems, such as thermal deformation, by adjusting welding technique. Students also learn to improve weld quality by optimizing important welding parameters such as wire feed rate, robot speed, inert gas shield and voltage. These switching machines made their debut towards around the 19th-century end. They were simple machines controlled remotely by a telephone user, either by pushing the buttons or turning the dial on the phone. Lower the cost of production, including both direct and indirect labor. BusinessTech by Hashmicro is where you will find the latest news about how technology can improve the business work-flow.

This integration allows individual processes to exchange information with each part. Manufacturing can be faster and less error-prone by the integration of computers. Typically CIM relies on closed-loop control processes based on real-time input from sensors. The Current state of expectations is that Computer Integrated Manufacturing will ulti mately determine the industrial growth of world nations within the next few decades. CIM represents a new production approach which will allow the factories to deliver a high variety of products at a low cost and with short production cycles. The new technologies for CIM are needed to develop manufacturing environments that are smarter, faster, close-cou pled, integrated, optimized, and flexible.

Computer-integrated manufacturing helps businesses to respond increasingly responsive to market customer needs. Computer-Integrated Manufacturing is a concept for integrating different business processes with automated functions in a manufacturing system. CIM can minimize lead time as well as preparation considerably. CIM also substantially reduces the usage of human resources in manufacturing. Successful implementation of CIM means optimization of the entire process instead of individual production processes.

The flexibility of a business process is defined as the adjustability to meet immediate and/or long-term customer needs as business conditions change. Information technologies such as computer-integrated manufacturing and group technology allow organizations to adopt a more flexible way of manufacturing and to increase customer responsiveness. IS also help companies cope with market conditions in a flexible manner by providing faster and more exact information regarding customer needs, prices, and costs. Scalability is defined as the ability to significantly increase or decrease capacity without major disruption or excessive costs.